| Application | Aluminum magnesium master alloy is used in the following applications:

1. Hardeners: Used for enhancing physical and mechanical properties of metal alloys.

2. Grain Refiners: Used for controlling the dispersion of individual crystals in metals to produce a finer and more uniform grain

structure.

3. Modifiers & Special Alloys: Typically used to increase strength, ductility, and machinability. |

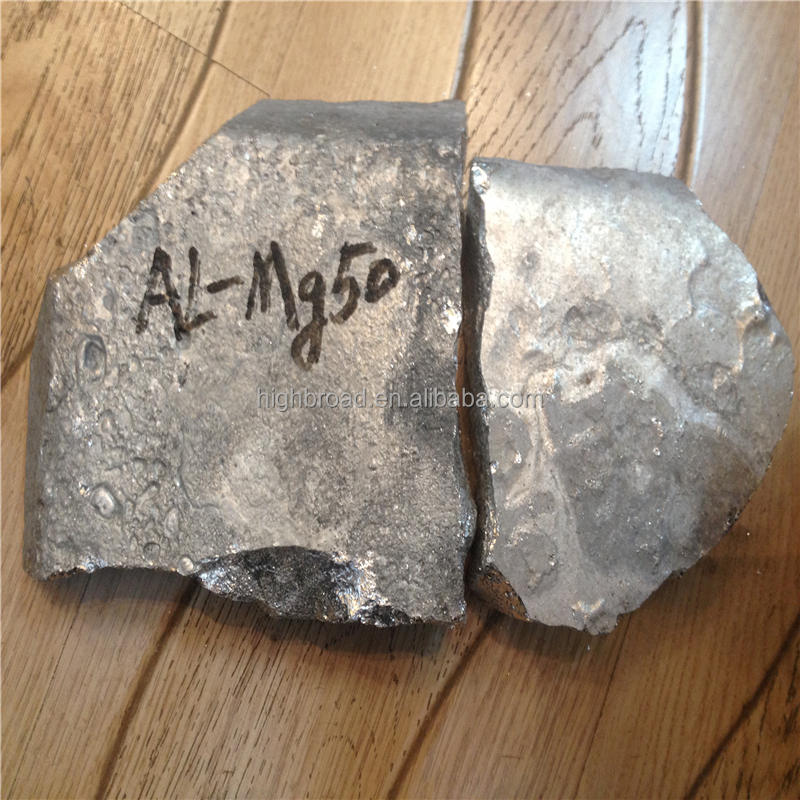

| Other Aluminium Products | AlMn, AlTi, AlNi, AlV, AlSr, AlZr, AlCa, AlLi, AlFe, AlCu, AlCr, AlB, AlRe, AlBe, AlBi, AlCo, AlMo, AlW, AlMg, AlZn, AlSn, AlCe, AlY, AlLa, AlPr, AlNd, AlYb, AlSc, etc. |

| Why use Master alloys? | There are several reasons for adding a Master Alloys to a melt, the main one being selective composition adjustment. They are used to modify the composition of the molten metal, allowing you to achieve a desired chemical specification. A second important application is for specific performance requirements. Master Alloys have the ability to change the micro-structure of a metal

during casting and solidification in order to change its properties. Properties that can be modified include: castability, surface finish, electrical conductivity, mechanical strength or ductility. The use of a Master Alloy instead of a pure metal can be for economical reasons, since certain elements will have a poor yield or create high losses when melted in pure form. Technical issues may also prevent the pure metals from dissolving completely or the required furnace temperature is too high for a basic casting operations equipment. Our Master Alloys provide the solution by

dissolving quicker at lower temperatures while saving valuable time and energy. |